[Marlin] G002-G003 - Arc or Circle Move

📅Update: 2020/09/18

Description

G2 adds a clockwise arc move to the planner; G3 adds a counter-clockwise arc. An arc move starts at the current position and ends at the given XYZ, pivoting around a center-point offset given by I and J or R.

CNC_WORKSPACE_PLANES allows G2/G3 to operate in the selected XY, ZX, or YZ workspace plane.

This command has two forms:

I J Form

Ispecifies an X offset.Jspecifies a Y offset.At least one of the

IJparameters is required.XandYcan be omitted to do a complete circle.The given

XYis not error-checked.The arc ends based on the angle of the destination.

Mixing

IorJwithRwill throw an error.

R Form

Rspecifies the radius.XorYis required.Omitting both

XandYwill throw an error.XorYmust differ from the current XY position.Mixing

RwithIorJwill throw an error.

Arc moves actually generate several short straight-line moves, the length of which are determined by the configuration option MM_PER_ARC_SEGMENT (default 1mm). Any change in the Z position is linearly interpolated over the whole arc.

'ARC_P_CIRCLES' enables the use of the 'P' parameter to specify complete circles

Usage

G2 [E<pos>] I<offset> J<offset> [P<rate>] R<radius> [X<pos>] [Y<pos>] [Z<pos>]

Parameters

[E<pos>]The amount to extrude between the start point and end pointI<offset>An offset from the current X position to use as the arc centerJ<offset>An offset from the current Y position to use as the arc center[P<rate>]Specify complete circles - requiresARC_P_CIRCLESR<radius>A radius from the current XY position to use as the arc center[X<pos>]A coordinate on the X axis[Y<pos>]A coordinate on the Y axis[Z<pos>]A coordinate on the Z axis

Gallery

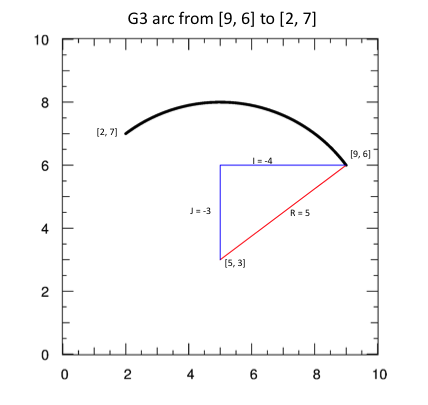

G3 command geometry

This illustrates a counter clockwise arc, starting at [9, 6]. It can be generated either by G3 X2 Y7 I-4 J-3 or G3 X2 Y7 R5

examples:

Move in a clockwise arc from the current position to [125, 32] with the center offset from the current position by (10.5, 10.5).

Move in a counter-clockwise arc from the current position to [125, 32] with the center offset from the current position by (10.5, 10.5).

Move in a complete clockwise circle with the center offset from the current position by [20, 20].

Last updated